How Huawei Reduces Design Time and Improves Confidence in Thermal Models

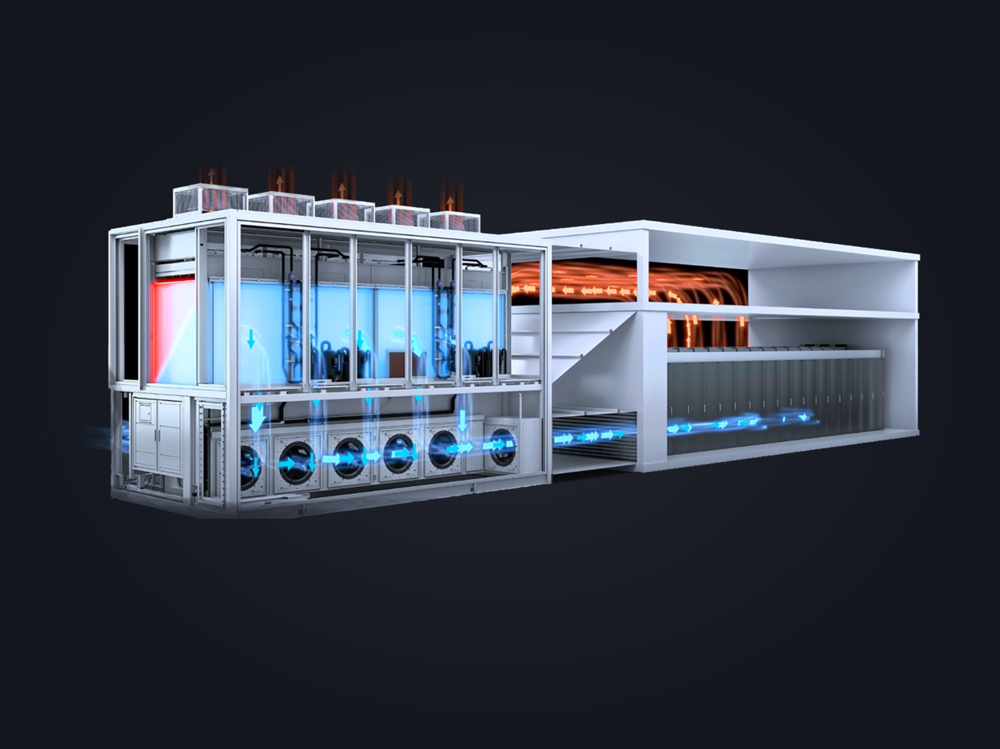

In the world of communication device design, manufacturers face a critical challenge: packing more processing power into smaller devices without compromising thermal performance. For companies like Huawei, which designs and manufactures cutting-edge communication devices, ensuring precise thermal modeling is a priority.

As device complexity increases with multi-core SoCs (system-on-chips) and SiP (system-in-package) designs, the need for accurate thermal analysis has never been greater. Huawei has turned to advanced simulation and testing tools to maintain optimal thermal performance in their devices, reducing design time and improving confidence in the accuracy of their thermal models.

The Thermal Modeling Challenge

The trend in modern communication devices is toward higher computing power in smaller form factors. However, with more cores generating significant heat in confined spaces, the challenge becomes how to dissipate this heat efficiently. Devices like multi-core SoCs require careful thermal management to avoid overheating and ensure the devices maintain their performance.

Historically, manufacturers used a SiP approach where chips were mounted side-by-side, but with increasing production volumes, stacked silicon die has become a more cost-effective method. This change, while reducing costs, increases the complexity of thermal modeling, especially when trying to meet tight size, weight, and form factor goals.

Huawei’s Approach: Leveraging Simcenter Tools

To tackle the growing challenges in thermal design, Huawei has incorporated Siemens’ Simcenter tools, including Simcenter Micred T3STER and Simcenter Flotherm. These tools work together to create highly accurate thermal models and provide detailed thermal analysis throughout the product development phase.

Huawei’s approach integrates hardware testing with simulation to refine thermal models. By using Simcenter Micred T3STER for transient thermal testing and Simcenter Flotherm for simulation, Huawei is able to reduce design time and improve the reliability of its thermal models. This combination offers high-fidelity results that are essential for designing next-generation communication devices.

The Measurement and Simulation Process

Huawei’s team used a three-core SoC device as a test vehicle for its new thermal design process. The device was assembled in a package-on-package format to facilitate better thermal management in confined spaces. The testing process started immediately after production, using Simcenter Micred T3STER to record the temperature response of the part. The tool measures the temperature changes from the power step and provides accurate results with an uncertainty of just ±0.01°C.

Once the physical tests were conducted, Huawei performed a transient simulation in Simcenter Flotherm using the best available information about the package design. This created an initial model, which was then compared to the experimental data. The temperature vs. time graphs showed good initial agreement, but deeper analysis revealed discrepancies that indicated the model needed refinement.

Model Calibration with Simcenter Flotherm

To address these discrepancies, Huawei used Simcenter Flotherm’s calibration tools to adjust the model. Using a technique called “structure function comparison,” Huawei was able to identify areas where the model was underestimating temperature rise. The calibration was automated using Simcenter’s optimization feature, which automatically adjusted several parameters like material thickness, thermal conductivities, and bond line resistances.

By selecting key parameters and running optimization, Huawei achieved a model that provided an excellent match to the measured results. This process significantly reduced the time and resources needed to refine the thermal model compared to manual adjustments.

Impact on Huawei’s Design Process

The ability to quickly create accurate thermal models has had a transformative impact on Huawei’s design workflow. By leveraging high-quality thermal data and simulation tools, Huawei is able to test multiple material selections and optimize designs more efficiently. The calibration process not only ensures better thermal performance but also helps the company reduce thermal resistance, enabling the development of more powerful devices that don’t overheat.

This advancement in thermal modeling gives Huawei a competitive edge in the rapidly evolving communication device industry. The ability to accurately predict thermal performance and optimize designs early in the development cycle allows Huawei to bring products to market faster, offering high-performance devices that meet the stringent demands of modern communication technologies.

Through the integration of Simcenter Micred T3STER and Simcenter Flotherm, Huawei has revolutionized its thermal design process, making it faster, more accurate, and more resource-efficient. This innovation not only helps Huawei manage the complex thermal challenges of next-generation devices but also improves their overall system-level modeling confidence. As a result, Huawei continues to lead in delivering high-performance communication devices to the market ahead of competitors.